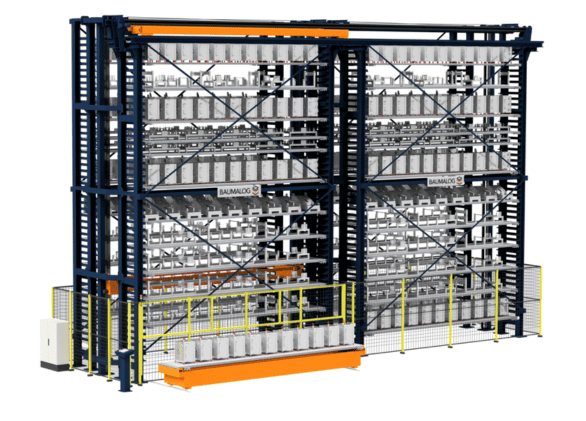

TransferTower® automated storage system

TransferTower® automated storage system consists of 2 to 4 TwinTower® systems connected each other with a transfer station, that enables the shelves transport between storage columns. The transfer station moves in the top section of the system and the shelves are transported to the station through the extractor that moves between storage columns. TransferTower® automated storage system is a perfect solution to store heavy tools like dies, technical instruments or spare parts. The system can be used as a functional storage system in many tool store ensuring safe storage of goods and saving storage space. The connection between the towers by the transfer station ensures access to all goods stored inside the system through all loading-unloading stations. The TransferTower® automated storage system can be placed in series to the shorter or longer side of the shelf.

Advantages

- access to all goods stored in multiple storage columns through each loading-unloading stations

- possible simultaneous picking and loading of goods

- optimalization of storage space

- control over warehouse and manufacturing processes possible due to integration with ERP and WMS systems

- work safety increase

Features of the TransferTower® system

- max. system height – 20 m

- max. shelf capacity – 5 000 kg

- max. shelf length – 12 m

- possible shelf construction with solid floor

- modular construction of the system

- possible outdoor installation

- possible use of loading-unloading stations that move along the shorter or longer side of the shelf

- the loading-unloading stations can be placed on different levels of the building

- loading and unloading process can be executed with forklift, jib crane or manually

- controlling software made by Baumalog (possible integration with ERP/WMS)