Automated sheet metal racking system – solution for increasing storage effectiveness

Automated sheet metal racking system is not just about storing a large volume of material in one place. Automation offers the opportunity to shorten time of intralogistic operations, make them safer and more efficient. Our storage systems automates the process from the moment the material is received into the magazine, through effective management into the system, e.g. by monitoring the position and stock levels, to the exit of the material from the warehouse and the transition to the next production stages. Automatic sheet metal storage offers the possibility of integrating the automation of production machines, e.g. laser cutting machines, press brakes or bending centres. In this way, storage processes become part of the entire integrated production process.

Baumalog automated sheet metal storage system are offered in many configurations in order to meet the needs of the customer – mainly storage needs in terms of volume and available space. Automated sheet metal racking systems are an opportunity to change the nature of storage processes – from expensive and time-consuming, they can change to real value for the company.

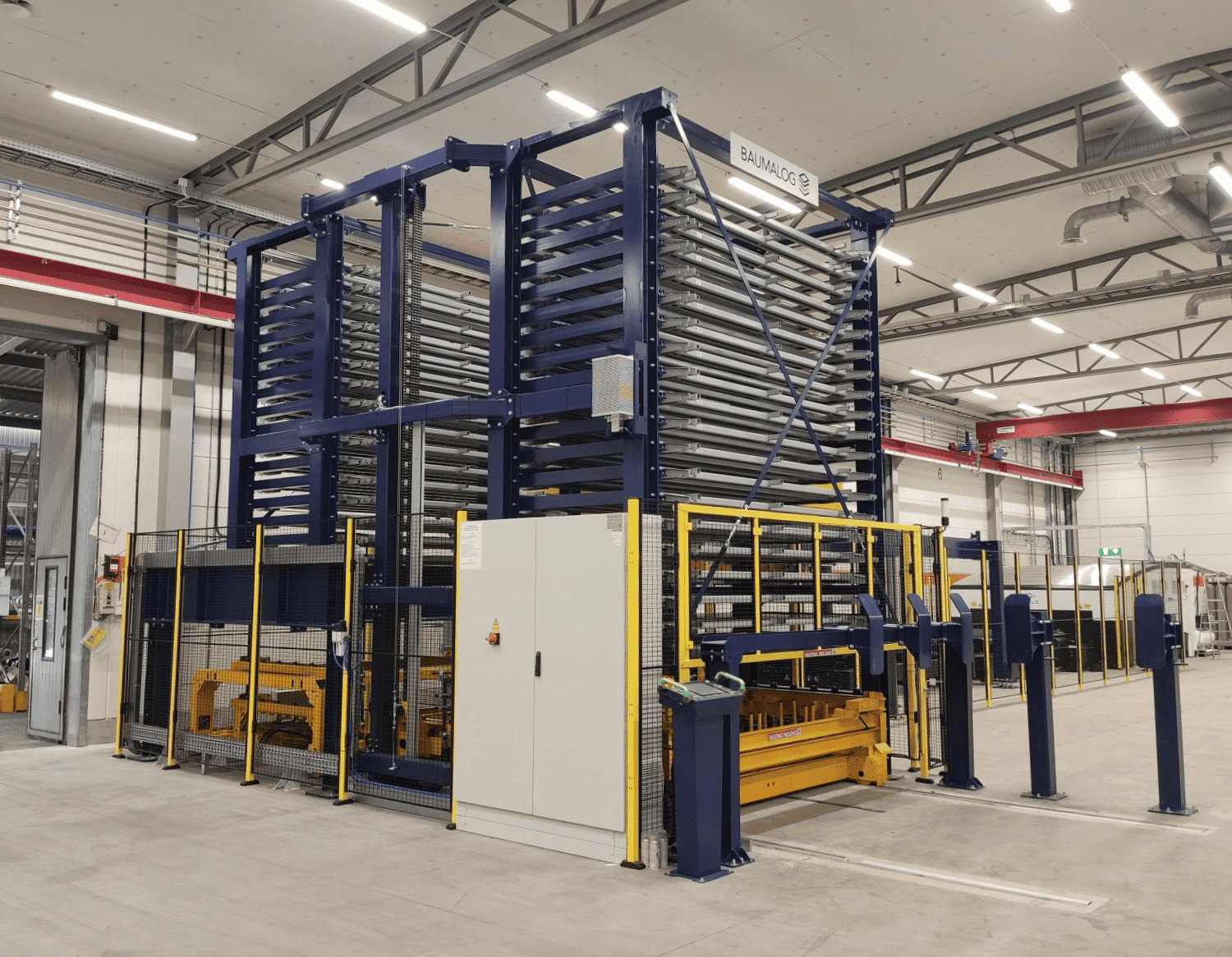

Automated sheet metal racking system from Baumalog

For more than 12 years, Baumalog has been comprehensively involved in the production of automated racking systems for metal sheets, long goods or tools as well as automation production systems, being responsible for the entire process – from the analysis of the customer’s needs, through design, manufacture, assembly and after-sales service. For more than a 10 years, Baumalog automated systems have been supplied to more than 100 companies where intralogistics processes have been improved thanks to them. Below is a range our sheet metal storage solutions.

Compact sheet metal racking system – MonoTower Lite

The MonoTower Lite automated sheet metal storage system is designed for the storage of up to 81 tonnes of sheet metal with maximum dimensions of 3 m x 1.5 m in an area of only 16 m2. Quick access to the stored sheet packs is provided by a lift that replaces the forklift truck, transporting the material shelf to the appropriate place in the storage column and delivering it back to the operator. In direct connection with the storage system, there is a depalletiser, which enables sheet packs to be automatically separated from pallets. The compactness and simplicity of the MonoTower Lite automated storage system allows for quick installation.

A single-column system with bigger capacity – MonoTower

The MonoTower automated racking system – like the Lite version – consists of a single storage column, but allows the storage of sheet packs with maximum dimensions of 3 m x 1.5 m, as well as 4 m x 2 m and 6 m x 2 m. The load capacity per shelf, depending on the size of the sheet metal bundles to be stored, ranges from 3 to 5 tonnes, and the entire system is as much as 160 tonnes in one automated storage column. Management of the system’s operation is facilitated by Smart WMS Standard software. The system is operated – as in all cases – by the operator panel.

TwinTower – two-column automated sheet metal racking system

The TwinTower automated metal sheet storage system has two storage columns, between which operates an automatic lift, responsible for the efficient execution of the operations inside the storage system . The maximum height of the TwinTower sheet metal racking system is 20 metres. Depending on the client’s needs, it is also possible to extend the warehouse to larger versions by adding more storage columns. The TwinTower metal sheet racking system can store up to 775 tonnes of metal sheets.

Multi-column automated warehouses

When storing larger volumes of material, it may be necessary to use more space for the storage system. Automated multi-column storage system such as TransferTower and MultiTower are solutions that offer the possibility of efficiently storing and managing large volumes of material.

TransferTower – storage system connected by a transfer station

TransferTower is an automated storage system which consists of two to four TwinTower automated racking system. The connection between the individual columns is provided by a transfer station, which allows the shelves to move across the entire width of the system. Between each pair of storage columns there are automatic lifts which are responsible for the vertical movement of the shelves. The TransferTower automated storage system has a maximum height of 20 m and a shelf load up to 5,000 kg.

MultiTower automatic sheet metal racking system with stacker crane

The MultiTower automated storage system offers the biggest possibilities in terms of storage volume. The MultiTower system is operated by a stacker crane which runs on a track between the storage columns. The stacker crane is integrated into the loading and unloading stations of the automated sheet metal racking system, which streamlines the process of loading the automated warehouse and delivering the sheets to the line machines.

Automatic sheet metal racking as a competitive advantage of a company

In any company, storage processes need to be properly planned. Today, the role of automation in storage processes is steadily increasing, enabling individual operations to be carried out more efficiently, which translates into increased efficiency throughout the process. Automated sheet metal racking system offers the possibility of linking up with processing machines such as laser cutting machines, creating a consistent process from the receipt of material into the storage, through effective storage, the flow of material, automated loading and unloading of the machine and the return of cut parts to the storage or access points. Automating a number of activities in the storage process also means safer and more efficient work for the operator. In a word, automation changes the picture of storage processes in terms of both cost and process.

Check the full offer of Baumalog sheet metal storage system: LINK

Follow us!