The cost of automation. How much does it cost to automate laser cutting machines?

Rising employment costs, difficulties in recruiting reliable employees or increased competition and falling series lengths in terms of order volumes are just some of the challenges that present businesses with the need to reorganise their production process. Such reorganisation always involves the challenge of maintaining or increasing the efficiency of the production process.

The best answer to the challenges of today’s market and an opportunity to increase the efficiency of the entire production is automation. In the following article, we answer the question of how much it costs to automate laser cutting machines in different configurations. The text is based on examples of the implementation of specific Baumalog systems.

The importance of laser cutting machines automation

Today’s laser cutting machines provide very fast cutting of various types of sheet metal – black, stainless or aluminium – with thicknesses ranging from 0.5 mm to 25 mm or even 50 mm. Using a fibre laser source of up to 40 kW or more, linear motors and other solutions used in modern laser cutting machines, extremely fast and high-quality cutting is ensured.

The main obstacle to achieving the full productivity of a laser cutting machine is the efficiency of its loading and unloading. Without automation of the machine, this process requires constant operator involvement.

Automated production without an operator

The automation of machines such as laser cutting machines is a solution that allows fully automated loading of the laser table and unloading of the cut parts, as well as access to a wide range of metal sheets, thanks to the connection to an automated storage system.

The task of the automation is to transport the correct sheet of metal to the laser cutting machine table at the right time and to collect it from the cutting machine table after the cutting process is completed and put it in the right place. The entire process is carried out without the operator.

Cost of automation – our examples

The final price of an automation system always depends on its size and complexity. Most often, the proposed solution requires precise calculations. Below I present the estimated costs of our systems in basic configurations.

In all cases, we assume the automation of a laser cutting machine in the most popular format – for cutting sheets with maximum dimensions of 3 m x 1.5 m.

We provide an estimation for three different configurations of automation systems:

- automated loading and unloading system for one laser cutter,

- automated loading and unloading system for one laser cutting machine integrated with the automated storage system,

- automated loading and unloading system integrated with the automated storage system for multiple laser cutting machines.

The cost of automating a single modern laser cutting machine is approximately EUR 105,000.

This includes the automated loading and unloading system of the cutting machine tables itself, which makes it possible to eliminate the physical work of the operator. However, the operator is still needed to change the range of cutting sheets and to supply pallets for unloading the cut-out parts. [More information about the system: Loader]

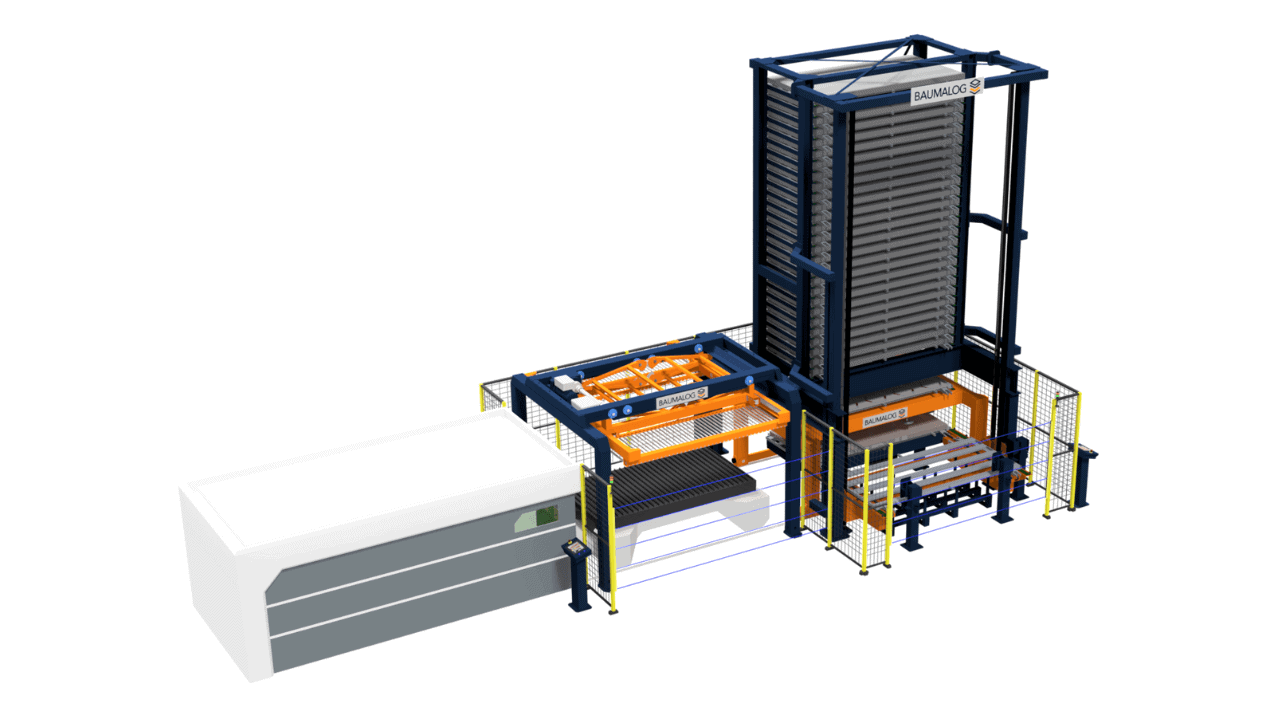

The cost of the automation of one laser cutting machine integrated with an automated storage system for sheet metal is approximately EUR 145,000.

With this system, the customer, in addition to automated loading and unloading, gains access to a storage system in the immediate proximity of the processing machine, which eliminates the physical work of the machine operator, provides access to various materials in less than 3 minutes and gives the possibility to put the cut parts back into the storage system. [More information about the system: Loader with storage system].

The cost of automation of several laser cutting machines with automated sheet metal storage is min. EUR 355,000.

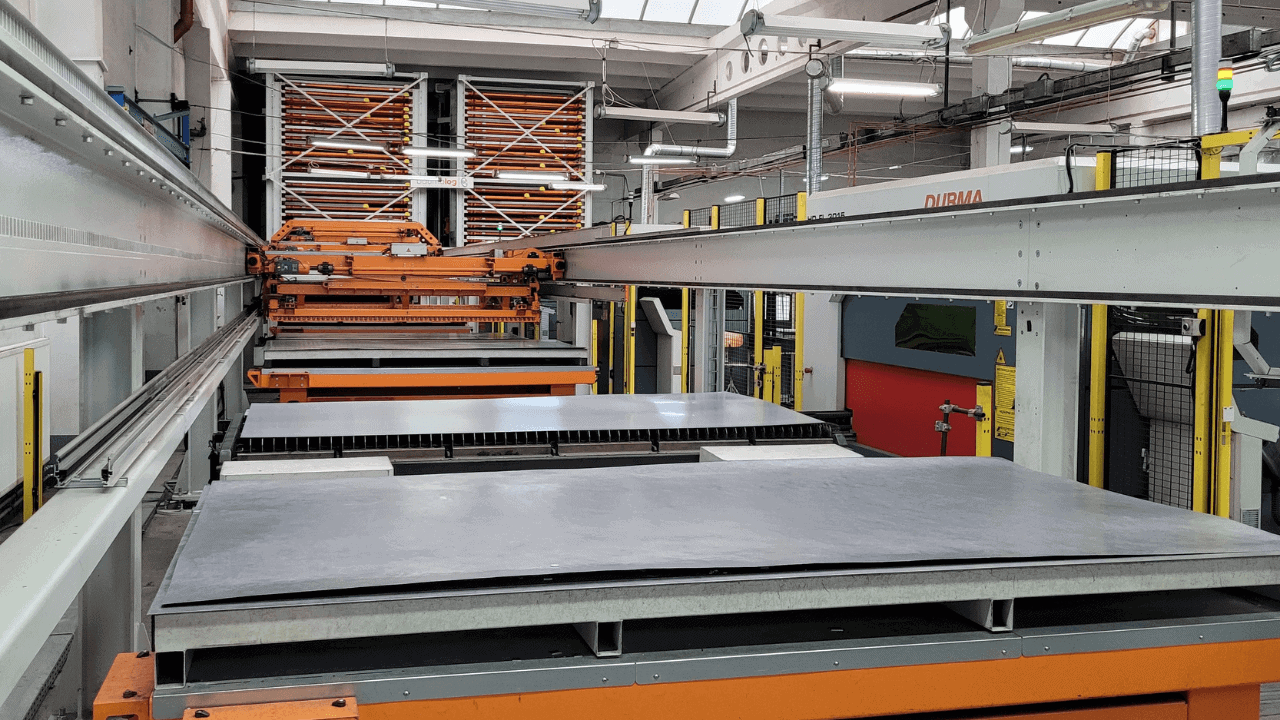

The most complex system, automating several laser cutting machines, is equipped with 2 independent modules – loading and unloading – which move along a correspondingly long track that connects the lasers to the storage system and access points for receiving the cut-out parts. The access points can also provide an additional loading area for raw material. [More information about the system: SmartFlow System].

Benefits of implementing an automation system

Automating the operation of the machine park guarantees an increase in the effective working time of the cutting machine by up to several times, due to the absence of the need for manual operation and its constant presence of the operator. Thanks to automation, sheet processing can be carried out in 2 or 3 shifts, even at weekends, without the need for constant operator control.

You can find up-to-date information about our company, new implementations, their results and much more on our social media: